Types of Flow Sensors Used in Industrial Automation

Introduction

Importance of flow sensors in industrial automation

Flow sensors play a crucial role in industrial automation systems by measuring and monitoring the flow of various fluids, gases, or liquids in a wide range of applications. These sensors provide essential information about the rate of flow, volume, pressure, and temperature of the fluid being transported within a system. Here are some key reasons why flow sensors are important in industrial automation:

Process control and optimization: Flow sensors enable precise control and optimization of industrial processes by providing real-time data on the flow rate. This information allows automation systems to adjust valves, pumps, or other control devices to maintain desired flow rates, ensuring efficient operation and minimizing wastage.

Quality control: In many manufacturing processes, maintaining consistent flow rates is critical for ensuring product quality and consistency. Flow sensors help detect any variations or deviations in the flow, allowing immediate corrective actions to be taken to prevent defects or inconsistencies in the final product.

Energy efficiency: Flow sensors enable energy-efficient operation by ensuring that pumps, compressors, or other fluid handling equipment are operating at the optimal flow rates. By monitoring and controlling flow, unnecessary energy consumption can be minimized, leading to cost savings and reduced environmental impact.

Equipment protection: Flow sensors can help protect industrial equipment from damage caused by improper flow conditions. For example, low or no-flow conditions can trigger alarms or shutdown mechanisms, preventing equipment damage or failure due to dry running or overheating.

Safety and environmental compliance: Flow sensors are crucial for ensuring safety and compliance with environmental regulations. By monitoring flow rates, they can detect any abnormal conditions such as leaks, blockages, or excessive pressure, which could pose safety risks or result in environmental hazards. Prompt detection and response to such conditions help prevent accidents, spills, or other undesirable incidents.

Data collection and analysis: Flow sensors provide valuable data for process monitoring, optimization, and data-driven decision-making. The data collected from flow sensors can be analyzed to identify trends, patterns, or anomalies, aiding in predictive maintenance, system troubleshooting, and overall process improvement.

Shortly, flow sensors are essential components of industrial automation systems, enabling precise control, optimizing processes, ensuring quality, improving energy efficiency, protecting equipment, maintaining safety, and facilitating data-driven decision-making. Their importance cannot be overstated in achieving efficient and reliable operation in various industrial sectors.

Overview of the different types of flow sensors

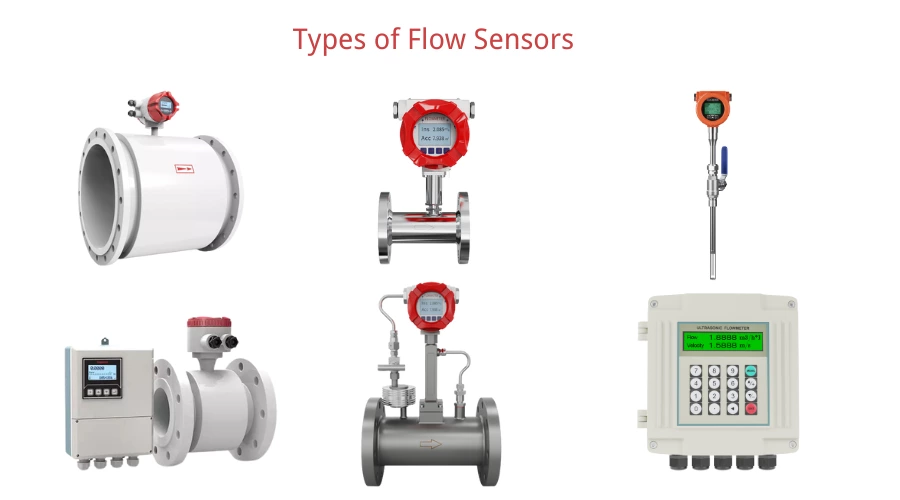

We discuss four types of flow sensors mainly, namely, mechanical flow sensors, thermal flow sensors, ultrasonic flow sensors, magnetic flow sensors, and Coriolis flow sensors.

Firstly, mechanical flow sensors are devices used to measure the flow rate of liquids or gases in a system. They are commonly used in industrial, commercial, and residential settings to monitor the flow of fluids for various applications. These sensors work by using a mechanical mechanism to detect the flow of fluid and convert it into an electrical signal that can be interpreted by a controller or monitoring system.

Secondly, thermal flow sensors are devices used to measure the flow rate of fluids by detecting changes in temperature. These sensors are commonly used in a variety of applications, including HVAC systems, industrial processes, and medical equipment.

Thirdly, ultrasonic flow sensors are devices that are used to measure the flow rate of fluids in a variety of applications. These sensors work by emitting ultrasonic waves into the fluid and then measuring the time it takes for the waves to travel through the fluid and return to the sensor. By analyzing this data, the sensor can calculate the flow rate of the fluid.

Finally, Coriolis flow sensors are devices used to measure the flow rate of fluids. They work on the principle of Coriolis force, which is the apparent force that acts on a body moving in a rotating frame of reference. The sensors consist of a vibrating tube that is subjected to the flow of the fluid. The vibration of the tube causes it to twist in a way that is proportional to the mass flow rate of the fluid.

Flow Measurement

Definition and significance of flow measurement in industrial processes

Flow measurement refers to the process of quantifying the rate of fluid flow within an industrial system. It involves the determination of the volume, mass, or velocity of a fluid moving through a specific point or along a particular pathway. Flow measurement is crucial in industrial processes as it provides essential information for process control, optimization, and safety.

The significance of flow measurement in industrial processes can be understood through the following points:

Process Control: Accurate flow measurement allows operators to monitor and control the flow rates of fluids within a system. By maintaining the desired flow rates, operators can ensure consistent product quality, optimize production efficiency, and avoid potential disruptions or failures.

Resource Management: Flow measurement helps in managing resources such as water, oil, gas, or chemicals by accurately measuring their consumption or utilization. This information enables industries to optimize their resource allocation, minimize waste, and improve overall operational efficiency.

Safety and Environmental Compliance: In many industries, such as chemical manufacturing or oil and gas, accurate flow measurement is critical for maintaining safety and ensuring compliance with environmental regulations. By monitoring flow rates, industries can detect leaks, pressure variations, or abnormal flow conditions that could pose safety risks or result in environmental hazards.

Energy Efficiency: Flow measurement plays a significant role in energy management within industrial processes. By precisely measuring flow rates, industries can identify opportunities for energy optimization, implement energy-saving measures, and reduce operational costs.

Process Optimization and Troubleshooting: Flow measurement data is often used for process optimization and troubleshooting purposes. By analyzing flow patterns and identifying any deviations or inefficiencies, industries can fine-tune their processes, identify potential bottlenecks, and improve overall system performance.

Billing and Custody Transfer: In industries where products or fluids are sold or transferred between entities, accurate flow measurement is essential for billing and custody transfer purposes. Reliable flow measurement ensures fair and accurate invoicing, preventing financial disputes and ensuring transparent transactions.

Flow measurement in industrial processes is crucial for maintaining process control, optimizing resource utilization, ensuring safety and environmental compliance, improving energy efficiency, and facilitating accurate billing and custody transfer. It enables industries to make informed decisions, enhance productivity, and ensure the smooth operation of their processes.

Understanding different flow measurement parameters

Flow Rate: Flow rate refers to the volume of fluid passing through a specific point or section of a pipe per unit of time. It is typically measured in units such as liters per minute (L/min), cubic meters per hour (m³/h), or gallons per minute (GPM). Flow rate provides information about the quantity or amount of fluid flowing in a system and is essential for process control, system optimization, and resource management.

Velocity: Velocity represents the speed at which the fluid is flowing. It is the rate of change of position of a fluid particle per unit of time. Velocity is usually measured in meters per second (m/s) or feet per second (ft/s). While flow rate provides information about the volume of fluid passing through a point, velocity indicates how quickly the fluid is moving. Velocity measurement is important for understanding fluid dynamics, pressure drop calculations, and determining flow characteristics within a system.

Mass Flow: Mass flow refers to the measurement of the mass of a fluid passing through a particular point per unit of time. It provides information about the actual amount of substance or material being transported by the fluid. Mass flow is commonly measured in units such as kilograms per second (kg/s) or pounds per hour (lb/h). Mass flow measurement is particularly important when dealing with fluids of different densities or when accurate mass control is critical, such as in chemical processes or custody transfer applications.

Totalized Flow: Totalized flow, also known as cumulative flow or total flow, represents the cumulative sum of the fluid that has passed through a system over a given period. It is the integration of flow rate or mass flow measurements over time. Totalized flow is typically measured in units such as liters (L), cubic meters (m³), or barrels (bbl). It provides a cumulative record of the fluid volume or mass, which is useful for tracking total consumption, monitoring system efficiency, billing purposes, or determining the remaining capacity of a storage vessel.

Understanding these flow measurement parameters is essential for accurately monitoring and controlling fluid flow within industrial processes. Each parameter provides valuable information about the characteristics, quantity, and movement of fluids, enabling effective process management, optimization, and decision-making.

Mechanical Flow Sensors

Types of mechanical flow sensors

Mechanical flow sensors, also known as flow meters, are devices used to measure the flow rate or velocity of fluids within a system. These sensors utilize mechanical principles to determine the movement or displacement of the fluid and convert it into a measurable output. Mechanical flow sensors are widely used in various industries, including oil and gas, water treatment, manufacturing, and HVAC (heating, ventilation, and air conditioning) systems.

Mechanical flow sensors come in different types and designs, each suitable for specific applications and fluid characteristics. Some common types of mechanical flow sensors include:

Differential Pressure Flowmeters: These flow sensors measure the pressure drop across a constriction or obstruction in the flow path, such as an orifice plate or a Venturi tube. By relating the pressure drop to the flow rate, these sensors provide an indirect measurement of flow. Examples of differential pressure flowmeters include orifice meters, venturi meters, and flow nozzles.

Positive Displacement Flowmeters: These sensors measure fluid flow by dividing it into discrete volumes or increments. They work by capturing and counting the volume of fluid passing through the metering chamber. Examples of positive displacement flowmeters include piston meters, oval gear meters, and nutating disc meters. These meters are highly accurate and suitable for measuring low flow rates and viscous fluids.

Turbine Flow Meters: Turbine flow sensors utilize a rotor with blades or vanes placed in the fluid stream. The flowing fluid causes the rotor to rotate, and the rotational speed is proportional to the flow rate. By measuring the rotor's speed, the flow rate can be determined. Turbine flowmeters are commonly used for measuring clean, low-viscosity fluids such as water and hydrocarbons.

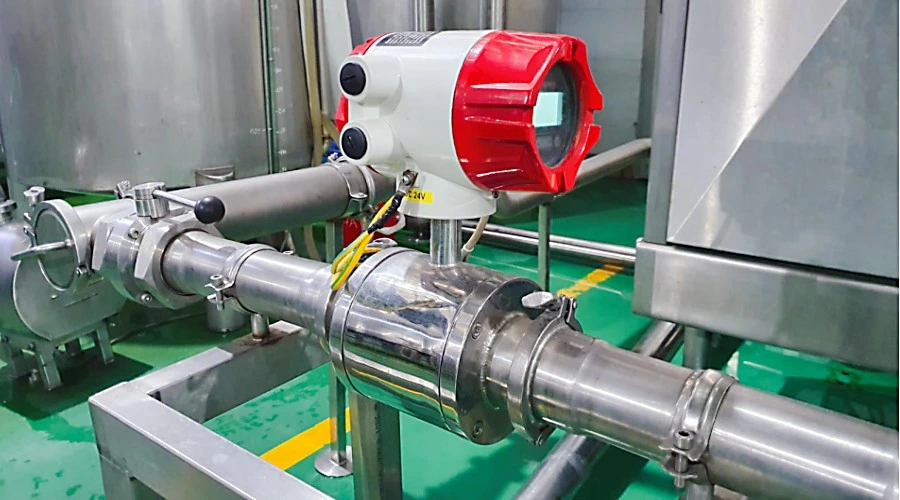

Vortex Flow Meters: Vortex flow sensors operate based on the principle of vortex shedding. They have a bluff body or shedder bar placed in the flow path. As the fluid flows past the bluff body, vortices are formed alternately on each side. The frequency of vortex shedding is proportional to the flow rate, allowing the measurement of flow. Vortex flowmeters are suitable for a wide range of fluids, including gases and liquids.

Magnetic Flowmeters: These flow sensors use the principle of electromagnetic induction to measure flow. They consist of a conductive pipe or tube through which the fluid flows and a magnetic field created by coils placed around the pipe. As the conductive fluid moves through the magnetic field, a voltage is induced, which is proportional to the flow rate. Magnetic flowmeters are commonly used for measuring conductive fluids, such as water and slurries.

Mechanical flow sensors provide reliable and cost-effective solutions for flow measurement in various industrial applications. They offer advantages such as simplicity, durability, and suitability for a wide range of fluid types and flow rates. However, it's important to consider factors such as accuracy requirements, fluid properties, and installation conditions when selecting a mechanical flow sensor for a specific application.

Thermal Flow Sensors

Introduction and types to thermal flow sensors

Thermal flow sensors are devices used to measure fluid flow based on the principle of heat transfer. These sensors utilize the changes in temperature caused by the fluid flow to determine the flow rate or velocity. Thermal flow sensors are commonly employed in various industries, including HVAC systems, gas and liquid flow monitoring, and industrial process control.

The operation of thermal flow sensors is based on the concept that the flow of a fluid carries away heat from a heated element or generates a temperature difference across a heated element. By measuring the resulting temperature changes, the flow rate can be determined. The two main types of thermal flow sensors are:

Constant Temperature Anemometers (CTAs): CTAs consist of a heated sensing element and one or more temperature sensors. The sensing element is heated to a constant temperature, and the fluid flow causes the cooling effect, resulting in a temperature difference between the heated element and the fluid. The temperature sensors measure this temperature difference, which is proportional to the flow rate. CTAs are commonly used for gas flow measurements.

Constant Current Anemometers (CCAs): CCAs, also known as hot wire anemometers, utilize a heated wire or filament as the sensing element. The wire is heated to a constant temperature by passing a constant electrical current through it. As the fluid flows over the wire, it causes a change in the cooling effect, altering the wire's resistance. By measuring this change in resistance, the flow rate can be determined. CCAs are commonly used for both gas and liquid flow measurements.

In addition to these main types, variations of thermal flow sensors include:

a. Inline Thermal Mass Flowmeters: These sensors measure the mass flow rate of a fluid by employing two temperature sensors and a heated element. The temperature difference between the two sensors is used to calculate the mass flow rate, while the heated element maintains a constant temperature differential.

b. Insertion Thermal Flowmeters: These sensors are designed to be inserted into the flow path of a pipe or duct. They utilize one or more heated elements and temperature sensors to measure the flow rate based on the cooling effect caused by the fluid flow.

c. Microbridge Mass Flow Sensors: Microbridge sensors employ a microfabricated thermal bridge with temperature sensors to measure flow rates. These sensors are highly sensitive and can accurately measure low flow rates and detect small changes in flow.

Thermal flow sensors offer advantages such as wide rangeability, fast response times, and the ability to measure both low and high flow rates. They are commonly used for gases, liquids, and multiphase flows. However, it's important to consider factors such as fluid properties, temperature range, pressure, and installation requirements when selecting a thermal flow sensor for a specific application.

Ultrasonic Flow Sensors

Types of Ultrasonic Flow Sensors

Transit-time Ultrasonic Flow Sensors:

a. Working Principle and Construction:

Transit-time ultrasonic flow sensors work based on the principle of measuring the time it takes for an ultrasonic signal to travel both upstream and downstream through the fluid. These sensors have two ultrasonic transducers positioned on opposite sides of the pipe. One transducer sends an ultrasonic signal diagonally across the pipe, while the other transducer receives the signal. The time difference between the upstream and downstream signals is used to determine the flow velocity and calculate the flow rate. Transit-time sensors can be further classified into clamp-on and inline types.

b. Advantages and Limitations:

Advantages of transit-time ultrasonic flow sensors include high accuracy, wide flow range capability, and the ability to measure clean fluids as well as fluids with small amounts of particulates. They are non-intrusive and do not cause pressure drop or flow obstruction. However, they may be affected by the presence of bubbles, foam, or aeration in the fluid, and they may require a certain minimum fluid velocity for accurate measurements.

Doppler Ultrasonic Flow Sensors:

a. Working Principle and Construction:

Doppler ultrasonic flow sensors operate based on the principle of the Doppler effect. These sensors emit ultrasonic signals into the flowing fluid, and the signals are reflected back by the suspended particles or bubbles in the fluid. The frequency shift of the reflected signals is proportional to the fluid velocity. By analyzing this frequency shift, the flow velocity and flow rate can be determined. Doppler sensors typically have one transducer for transmitting and receiving the ultrasonic signals.

b. Applications and Benefits:

Doppler ultrasonic flow sensors are particularly suitable for applications where the fluid contains suspended solids or bubbles, such as wastewater treatment or slurries. They can handle fluids with high particulate concentrations and are not affected by the fluid's acoustic properties. Doppler sensors offer advantages such as simplicity of installation, wide rangeability, and reliable measurements in challenging fluid conditions.

Overall, ultrasonic flow sensors provide a versatile and accurate solution for flow measurement in various industries. Transit-time sensors are effective for clean fluids, while Doppler sensors excel in applications involving suspensions or bubbles. The choice of ultrasonic flow sensor depends on the specific application requirements, fluid characteristics, and installation conditions.

Coriolis Flow Sensors

Coriolis flow sensors are advanced devices used to measure fluid flow rates based on the principle of the Coriolis effect. These sensors utilize vibrating tubes or meters to detect the twisting or bending motion caused by the fluid flowing through them. By measuring the changes in the vibration characteristics, Coriolis flow sensors can accurately determine flow rates and provide additional information such as density and temperature measurements. Coriolis flow sensors offer high accuracy, reliability, and versatility, making them suitable for a wide range of industrial applications.

Types of Coriolis Flow Sensors

There are two main types of Coriolis flow sensors commonly used:

Single-tube Coriolis Flow Sensors:

Single-tube Coriolis flow sensors consist of a single vibrating tube or meter through which the fluid flows. The tube is typically U-shaped or helical in design and is set into motion by an internal driver. As the fluid flows through the vibrating tube, the Coriolis effect causes a phase shift and twisting motion in the tube. This motion is measured by sensors, and the resulting data is used to calculate flow rates, density, and temperature. Single-tube Coriolis flow sensors offer high accuracy, particularly for low flow rates, and are suitable for a wide range of fluid types.

Multi-tube Coriolis Flow Sensors:

Multi-tube Coriolis flow sensors consist of multiple parallel vibrating tubes or meters. Each tube has its own driver and sensor setup. The fluid flows simultaneously through all the tubes, and the resulting motion and phase shifts are measured. By analyzing the data from multiple tubes, the flow rate, density, and temperature can be accurately determined. Multi-tube Coriolis flow sensors offer increased accuracy and are suitable for a broader range of flow rates and fluid types. They are commonly used in applications where high accuracy and versatility are required, such as custody transfer of fluids.

Coriolis flow sensors are widely used in industries such as oil and gas, chemical processing, pharmaceuticals, food and beverage, and water management. They offer benefits such as direct mass flow measurement, high accuracy, wide flow range capability, low pressure drop, and the ability to handle various fluid types and viscosities. Coriolis flow sensors play a crucial role in process control, optimization, and quality assurance by providing accurate and reliable flow measurements along with additional information about the fluid properties.

Frequently Asked Questions (FAQs)

Q1: What is the purpose of flow sensors in industrial automation?

Flow sensors in industrial automation are used to measure and monitor the flow of fluids within a system. Their purpose is to provide accurate and real-time information about flow rates, which is crucial for process control, optimization, resource management, and ensuring system efficiency and safety.

Q2: How do mechanical flow sensors work?

Mechanical flow sensors operate based on various principles such as differential pressure, positive displacement, turbine rotation, vortex shedding, or magnetic induction. These sensors utilize mechanical mechanisms or components to measure fluid flow characteristics such as pressure, displacement, rotation, or induction, which are then converted into flow rate measurements.

Q3: What are the advantages of using thermal flow sensors?

Advantages of thermal flow sensors include their ability to measure both gases and liquids, wide flow range capability, fast response times, low pressure drop, high accuracy, and suitability for various applications. They also offer non-intrusive measurement, low maintenance requirements, and the ability to measure low flow rates and detect small changes in flow.

Q4: What are the applications of ultrasonic flow sensors?

Ultrasonic flow sensors find applications in a wide range of industries, including water management, oil and gas, chemical processing, HVAC systems, and wastewater treatment. They are used for measuring flow rates of liquids or gases, even in challenging fluid conditions, and are suitable for both clean fluids and those containing suspended solids or bubbles.

Q5: What industries use magnetic flow sensors?

Magnetic flow sensors, also known as electromagnetic flow sensors, are commonly used in industries such as water and wastewater management, chemical processing, pulp and paper, and mining. They are particularly suitable for measuring the flow of conductive fluids, including water, slurries, and corrosive liquids.

Q6: What are the benefits of Coriolis flow sensors?

Coriolis flow sensors offer advantages such as high accuracy, direct mass flow measurement, measurement of density and temperature along with flow rate, wide rangeability, and the ability to handle a variety of fluid types. They are commonly used in industries such as oil and gas, pharmaceuticals, food and beverage, and chemical processing.

Q7: Can flow sensors be used for both liquids and gases?

Yes, flow sensors can be used for measuring both liquids and gases. However, it's important to select a flow sensor suitable for the specific fluid being measured, as different types of flow sensors may have varying performance characteristics and limitations depending on the fluid type.

Q8: How accurate are flow sensors in measuring flow rates?

The accuracy of flow sensors can vary depending on the type of sensor, the specific application, and the flow rate range being measured. However, modern flow sensors can offer high accuracy, with some capable of achieving accuracies within a few percentage points or even better, particularly in the case of ultrasonic and Coriolis flow sensors.

Q9: What factors should be considered when selecting a flow sensor?

When selecting a flow sensor, factors to consider include the fluid type, flow range, accuracy requirements, pressure and temperature conditions, compatibility with the fluid, installation considerations (such as space constraints or pipe size), maintenance requirements, and the overall cost-effectiveness for the specific application.

Q10: How can flow sensors contribute to process optimization?

Flow sensors provide real-time data on flow rates, enabling operators to monitor and control fluid flow within a system. This information can be used to optimize processes, identify inefficiencies or abnormalities, detect leaks or blockages, balance flow distribution, and ensure the system operates at optimal conditions. By utilizing flow sensors, industries can improve energy efficiency, reduce waste, enhance product quality, and optimize resource allocation.

Conclusion

Choosing the right flow sensor for specific applications is crucial for accurate and reliable flow measurement. Factors such as fluid type, flow rate range, accuracy requirements, pressure and temperature conditions, and installation considerations should be carefully considered. Selecting an inappropriate flow sensor can lead to inaccurate measurements, reduced system efficiency, and potential safety risks. By choosing the right flow sensor, industries can optimize their processes, improve energy efficiency, ensure product quality, and achieve cost-effectiveness.

Flow sensors play a vital role in industrial automation by providing accurate and real-time flow rate measurements. They enable process control, optimization, and resource management, ensuring the efficiency and safety of industrial processes. Flow sensors help industries monitor and regulate fluid flow, detect abnormalities, and make informed decisions for process improvements. With advancements in technology, flow sensors are becoming more accurate, versatile, and capable of handling various fluid types and flow conditions. As a result, they continue to be essential components in industrial automation, contributing to improved efficiency, sustainability, and productivity in a wide range of industries.