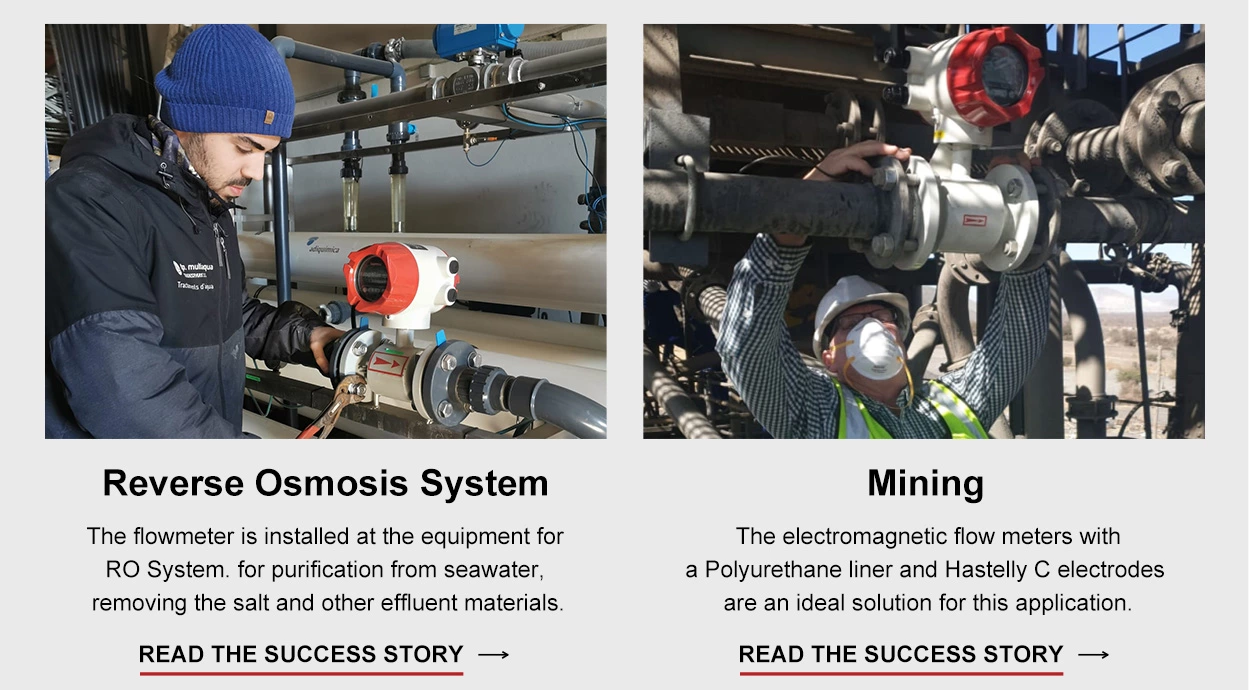

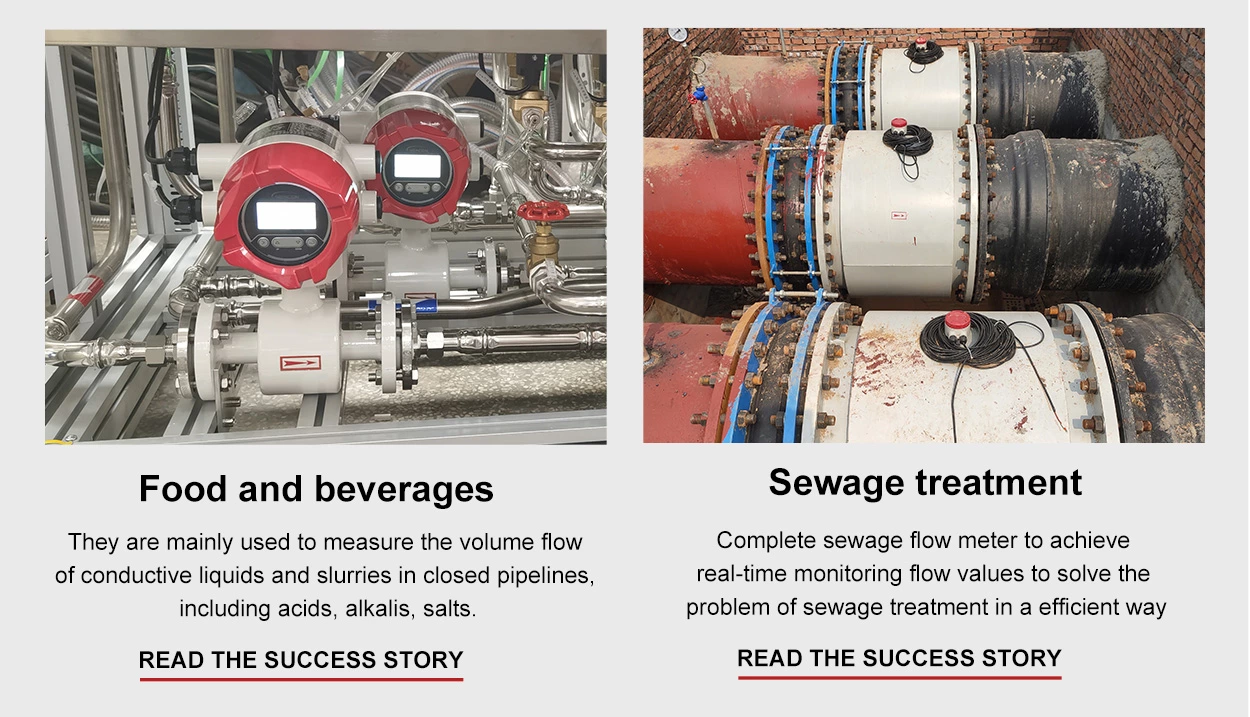

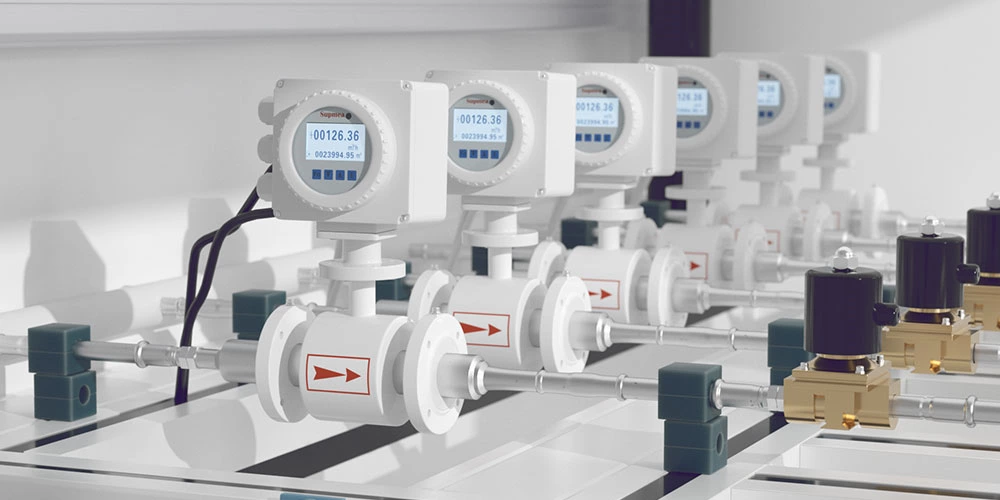

The SUP-FMC240 Supmea's electronic water meter does not contain any moving parts, rotating gears or turbines, or bearings. Instead, it relies on two electrodes to measure the density of the induced magnetic field that results from an electrically conductive fluid, such as water, flowing through a pipe. So there is no susceptibility to bearing wear or other mechanical wear-and-tear issues.

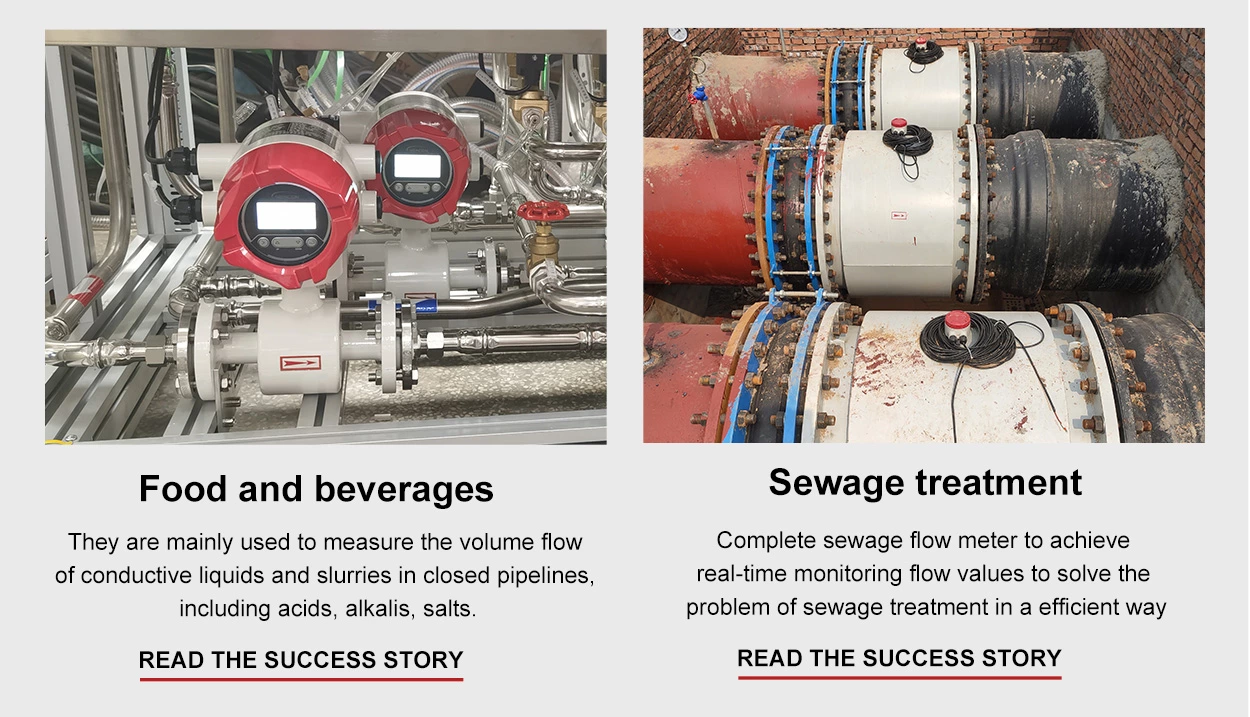

As for the electrodes and the liner used in electronic water meter, these components can be fabricated from a variety of materials to make the meter compatible with different conditions of water.

The only limitation of the electronic water meter is that the measured fluid media must be electrically conductive (>5μS/cm). Non-conductive fluids, such as oil and other petroleum-based fluids, cannot be measured with the technology.

| Product |

Electronic water meter |

| Model |

SUP-FMC240 |

| Diameter nominal |

DN15~DN1000 |

| Nominal pressure |

DN15 - DN250, PN ≤1.6MPa |

| DN300 - DN1000, PN ≤1.0MPa |

| Accuracy |

Class 2(Please see datasheet for details)

|

| Repetitiveness |

0.16% |

| Liner material |

Neoprene (CR), Polyurethane (PU), PTFE (F4), PFEP (F46), PFA |

| Electrode material |

316L Stainless Steel, Hastelloy C, Hastelloy B, Ti, Ta, Pt |

| Medium temperature |

Neoprene: -10…+70℃ Polyurethane: -10…+60℃ PTFE/FEP: -10…+120℃ PFA: -10…+120℃ |

| Power supply |

220VAC, 24VDC |

| Structure type |

Compact type, Remote type |

| Ingress protection |

IP65, IP68(remote type only) |

| Product standard |

JB/T 9248-2015 |

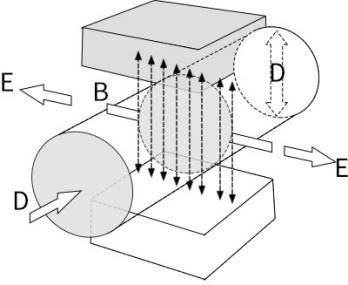

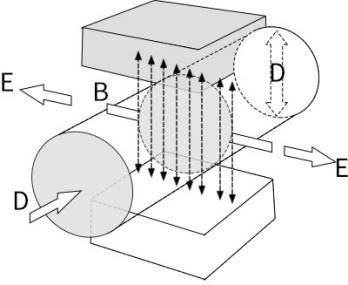

Mag meter works based on Faraday's law, when the liquid goes through the pipe at the flow rate of v with a diameter D, within which a magnetic flux density of B is created by an exciting coil, the following electromotive E is generated in proportion to flow speed v:

E=K×B×V×D

Where:

E-Induced electromotive force

K-Meter constant

B-Magnetic induction density

V-Average flow speed in cross-section of measuring tube

D-Inner diameter of measuring tube